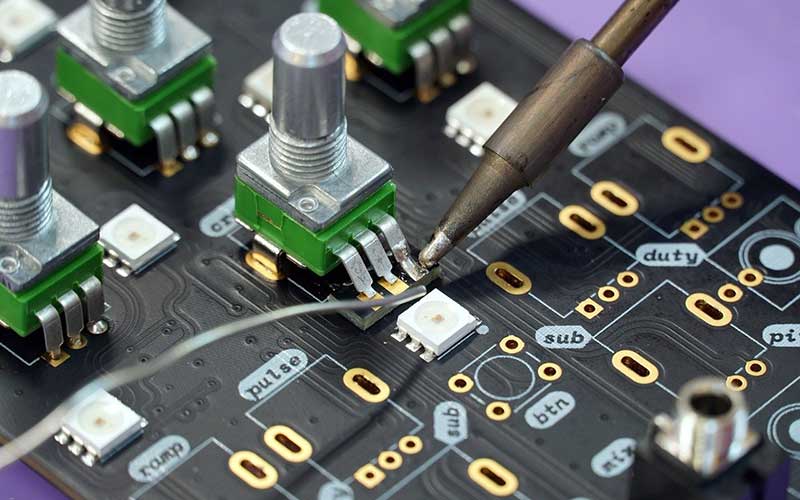

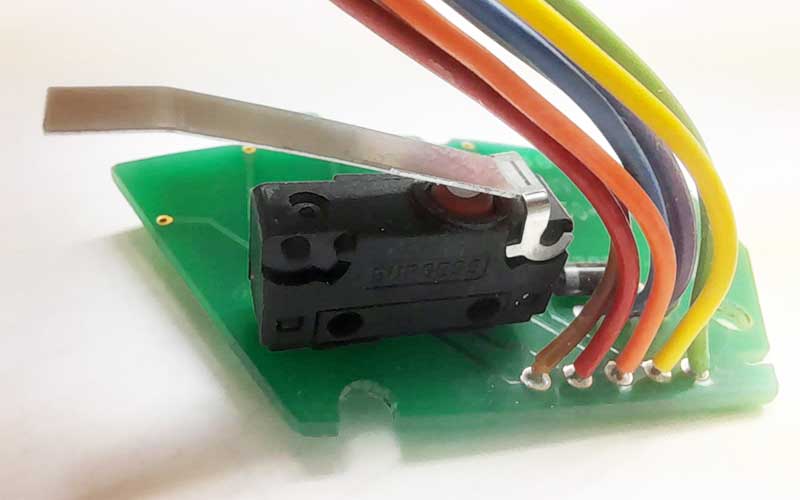

Soldering and tinning

Secure and durable connections

The importance of proper soldering and tinning technique

Soldering and tinning techniques are used to make electrical connections between cables, wires and electronic components. A high-quality solder joint ensures a durable and reliable electrical connection that remains stable even under extreme conditions. In addition, tin plating protects the copper conductors from corrosion and oxidation, which extends the service life of the cable.

Soldering and tinning techniques

In recent years, soldering and tinning techniques have evolved significantly. Here are some of the modern approaches used in cable assembly:

- Selective soldering: In selective soldering, the solder is applied specifically to the desired areas. This method is particularly useful when specific components are sensitive to high temperatures.

- Soldering robots: Automated soldering robots are capable of producing complex solder joints with precision. They offer not only high precision, but also improved efficiency and reproducibility.

Quality control and inspection

Quality assurance plays a decisive role in cable assembly. Modern techniques for quality assurance and inspection make it possible to detect and rectify faulty solder joints at an early stage. These include ultrasonic testing and optical inspection systems. These methods ensure that every cable manufactured at MTG Montagetechnik GmbH meets the highest quality standards.

Environmental aspects and sustainability

In today’s world, sustainability is an important factor in the electronics industry. Modern soldering and tinning techniques can help to reduce the consumption of solder and energy. Lead-free soldering processes, which MTG Montagetechnik GmbH uses, are mandatory in many regions to minimize environmental impact.

ConclusionAt MTG Montagetechnik GmbH, soldering and tinning technology plays a decisive role in cable assembly. Modern techniques and automation not only improve efficiency, but also the quality of the manufactured products. The continuous development of soldering and tinning techniques makes it possible to meet the ever-increasing demands of the electronics industry while minimizing environmental impact. In a world where electronic connections are becoming increasingly important, high-quality soldering and tinning techniques are indispensable.