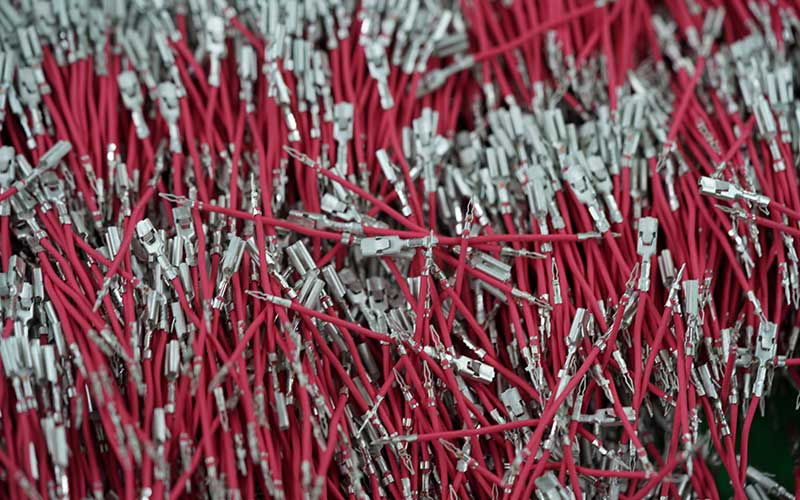

Crimp technology

Cables with cross sections from 0.14 mm² to 16 mm² are processed

Crimp connections play a crucial role in vehicle wiring and plug-in connections. In modern automobiles, countless electrical components and sensors are interconnected to ensure that the vehicle runs smoothly. This includes components such as sensors for engine performance, airbag systems, lighting systems and much more. A reliable connection is crucial here, as poor connections can lead to malfunctions or safety issues.

The crimping process ensures a secure, gas-tight and electrically conductive connection between the conductor and the contact. This means that the electrical signals can be transmitted without interference and without any interruptions or losses. Gas-tight connections are especially important to keep moisture and dirt away from sensitive electrical components, as they can affect performance.

The crimp connections is made by specifically squeezing a specially shaped crimp contact around the conductor. This contact is often made of high quality metal and provides excellent electrical conductivity. Crimping ensures that the conductor is held securely and firmly in place without slipping or coming loose, even in the most demanding conditions to which vehicles are subjected.

In the world of vehicle wiring and electrical engineering, crimp connections are therefore an indispensable technology for ensuring that electrical systems operate reliably and efficiently. They help ensure the safety and functionality of modern vehicles and exemplify the precision and care required in joining technology.